Plastisol Transfer on Promotional Items

Last Updated: 26 July 2025

Plastisol transfer branding provides a cost-effective method for decorating items. It merges the quality of screen printing with the speed of digital printing. This method also simplifies the process by eliminating the setup of screens and messy inks. Consequently, you save time by avoiding pressing and distributing ink on each unit. Once applied, the design adheres perfectly to deliver excellent results without hassle.

Two Major Types of Plastisol Transfer

- Cold Peel/ Cold-Split: With Cold Peel/Cold-Split transfers, you can quickly achieve vibrant graphics on dark-coloured shirts. This unique process utilises high pressure in combination with low heat and an adhesive that separates once exposed to cold temperatures. Therefore, if you’re looking to skip additional curing steps, this method is ideal as it guarantees a durable finish that can hold up through multiple washes.

- Hot Peel/ Hot-Split: In contrast to their cooler counterparts, these transfers demand high temperatures and a specialised adhesive, which work together to create vibrant graphics that last even longer. Specifically designed for lighter-coloured shirts, this technique not only reduces curing time but also allows you to get your designs onto the fabric more quickly. Moreover, with Hot Peel/Hot-Split transfers, you can elevate your designs with bold details and enjoy a longer wear life.

What are the Advantages of Heat Transfers?

- High-quality edge definition on rough or textured fabrics enhances the appearance of the materials.

- You can print designs in bulk and apply them to products as needed, which saves time on setups.

- Multiple logos of different sizes can be printed simultaneously to eliminate extra setup costs.

- The heat transfer process ensures that the quality print remains clear and crisp so that it adheres firmly to the fabric.

What are the Disadvantages of Using Transfers?

- The process involves extra costs because it requires more materials overall than some cheaper methods.

- The print has a distinct plastic-y feel, making it suitable only for isolated designs rather than an entire shirt or sweater.

- If care is not taken, exposure to hot irons can damage transfer prints.

Transfer vs Screen vs Digital Print Side by Side

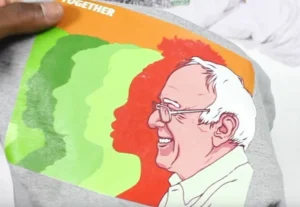

Please see a close up visual image of what a Transfer print looks like compared with other types of printing.

What Promotional Items Do You Brand Using Plastisol Heat Transfers?

This technique is particularly well suited to decorated headwear and clothing, including;

- Promotional caps

- Custom bucket hats

- Logo t-shirts

- Corporate polo shirts

- Personalised hoodies and sweaters

- Branded cotton shopping bags

- Non-woven supermarket bags

- and more!

Sale

Sale

Corporate Uniforms

Corporate Uniforms Eco Apparel

Eco Apparel Hoodies & Sweaters

Hoodies & Sweaters Jackets

Jackets Kids' Clothes

Kids' Clothes Other Apparel

Other Apparel Polo Shirts

Polo Shirts Socks

Socks Shoes

Shoes Sports Bottoms

Sports Bottoms Sports Uniforms

Sports Uniforms Singlets

Singlets Tee Shirts

Tee Shirts Workwear

Workwear

Briefcases

Briefcases Dry Bags

Dry Bags Laptop

Laptop Satchels

Satchels Specialised Bags

Specialised Bags Tote Bags

Tote Bags

Beanies

Beanies Caps

Caps Straw Hats

Straw Hats

Bottled Water

Bottled Water Drinkware Gift Sets

Drinkware Gift Sets Glass & Poly Cups

Glass & Poly Cups Mason Jars

Mason Jars Stubby | Bar & Drinkware

Stubby | Bar & Drinkware Wines

Wines

Business Card Holders

Business Card Holders IT Gift Sets

IT Gift Sets Tech Computers

Tech Computers

Beach Towels

Beach Towels Car Accessories

Car Accessories Golf

Golf Lighters

Lighters Picnic Gear

Picnic Gear Sports Items

Sports Items Sunscreens

Sunscreens

Markers

Markers Post-It & Sticky Notes

Post-It & Sticky Notes

Card Decks

Card Decks Coin Banks

Coin Banks Conference Toys

Conference Toys Event Toys

Event Toys Frisbees

Frisbees Games & Puzzles

Games & Puzzles Kids

Kids Plush Toys

Plush Toys

Print | Signage

Print | Signage

Antibacterial

Antibacterial Eco Products

Eco Products Gift Box Sets

Gift Box Sets Homeware

Homeware Pet Products

Pet Products Personal Care

Personal Care Occasion Ideas

Occasion Ideas