What is a Digitally Printed Label?

Last Updated: September 12,2025

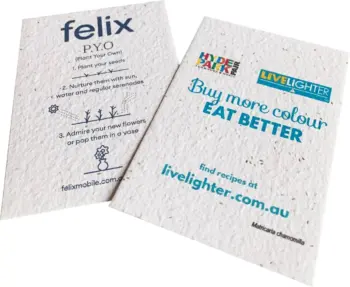

In the world of promotional products, a digitally printed label is a type of decoration method where your logo, artwork, or design is printed onto an adhesive label using digital technology. It is then applied to the product’s surface (often by hand). It’s often used when full-colour branding is required, especially for intricate logos with gradients, shading, or photographic elements.

Unlike screen printing or pad printing digital labels give you the freedom to reproduce almost any design exactly as it appears on your screen. They’re ideal for smaller quantities, fast turnaround times, or when you need your brand to look sharp and vibrant easily.

What is the Branding Process?

The process starts digitally—your artwork is prepared using graphic design software, ensuring it’s high-resolution and suitable for print. Then, a digital printer uses CMYK (cyan, magenta, yellow, and black) inks to reproduce your design onto a unique adhesive label, often made of vinyl or polyester.

Once printed, the label is cut to the correct shape (usually a square, rectangle, or custom die-cut) and carefully applied to the promotional product. The end result is a smooth, durable finish that looks polished and professional. Because the entire process is handled digitally, there’s no need for printing plates or colour separations. This eliminates the need for printing setups.

Advantages

One of the biggest benefits of digitally printed labels is full-colour capability. If your logo includes gradients, photos, or fine lines, digital printing captures all that detail.

It’s also ideal for shorter production runs, as it doesn’t require extensive setup. That means faster lead times and lower costs for smaller quantities—perfect if you’re doing a targeted campaign or event-specific promotion.

Digital labels are also versatile. They adhere well to many most flat clean surfaces including plastic, glass, cardboard, and metal. This makes them a go-to option when the product material is not suitable for holding onto ink.

Disadvantages

While digitally printed labels offer plenty of visual appeal, they do have some limitations. First, because they’re adhesive-based, they’re not as long-lasting as direct print methods like screen printing or engraving. Afterall it is a sticker and will peal off over time. Over time a digitally printed label will peel off. Extreme cold, heat, water, or regular friction will deteriorate stickers fast.

There’s also the question of texture. Since the label sits on top of the product rather than being printed directly, it can sometimes feel like a sticker. That’s not a problem for most users, but other branding methods may be better suited if you’re after a more seamless or tactile finish.

Finally, they’re usually not the best choice for massive print runs, as costs per unit can increase compared to methods optimised for bulk printing.

Examples of Promo Merch That Use Digitally Printed Labels

Examples of merchandise that use digitally printed labels to brand logos and event details include:

- promotional lipbalms

- promotional Hand Sanitizers

- Gift or presentation boxes

- Certain Notebooks

- Gift Box corporate gift sets

- custom branded colouring pencil sets

Digitally printed labels fill an important gap in the promotional branding toolkit. They give you colour accuracy, quick turnaround, and design flexibility that other methods struggle to match. If you’re working with a detailed logo or a fast-moving event campaign, they’re a smart, efficient way to bring your brand to life. Want to know if your promo item is suitable for this branding method? Just ask—we’ll guide you through it.

Sale

Sale

Corporate Uniforms

Corporate Uniforms Eco Apparel

Eco Apparel Hoodies & Sweaters

Hoodies & Sweaters Jackets

Jackets Kids' Clothes

Kids' Clothes Other Apparel

Other Apparel Polo Shirts

Polo Shirts Socks

Socks Shoes

Shoes Sports Bottoms

Sports Bottoms Sports Uniforms

Sports Uniforms Tee Shirts

Tee Shirts Workwear

Workwear

Briefcases

Briefcases Dry Bags

Dry Bags Laptop

Laptop Satchels

Satchels Specialised Bags

Specialised Bags Tote Bags

Tote Bags

Beanies

Beanies Caps

Caps Straw Hats

Straw Hats

Bottled Water

Bottled Water Drinkware Gift Sets

Drinkware Gift Sets Glass & Poly Cups

Glass & Poly Cups Mason Jars

Mason Jars Stubby | Bar & Drinkware

Stubby | Bar & Drinkware Wines

Wines

Business Card Holders

Business Card Holders IT Gift Sets

IT Gift Sets Tech Computers

Tech Computers

Beach Towels

Beach Towels Car Accessories

Car Accessories Golf

Golf Lighters

Lighters Picnic Gear

Picnic Gear Sports Items

Sports Items

Markers

Markers Post-It & Sticky Notes

Post-It & Sticky Notes

Card Decks

Card Decks Coin Banks

Coin Banks Conference Toys

Conference Toys Event Toys

Event Toys Frisbees

Frisbees Games & Puzzles

Games & Puzzles Kids

Kids Plush Toys

Plush Toys

Print | Signage

Print | Signage

Antibacterial

Antibacterial Eco Products

Eco Products Gift Box Sets

Gift Box Sets Homeware

Homeware Pet Products

Pet Products Personal Care

Personal Care Occasion Ideas

Occasion Ideas