There is something refreshing about knowing your branded merchandise was made right here in Australia. That’s exactly the story behind our Australian-made custom water bottles—a local manufacturing success that combines sustainability, quality, and rapid turnaround. And today, we’re pulling back the curtain to show you exactly where and how they’re made.

Why More Brands Are Choosing Australian Made

Whether you’re a business ordering bottles for a conference, a council promoting sustainability, or a school rewarding students, there’s growing demand for locally produced, custom-branded drinkware.

Here’s what’s driving it:

- 🐨 Supporting Aussie businesses and jobs

- 🚚 Faster lead times — for wholesale larger order volumes over 5000 units

- 🌏 Lower carbon footprint

- 🎯 Higher transparency and quality control

- 🧼 Better hygiene standards and compliance

So, when you choose a bottle made in Australia, you’re not just choosing a product.

Step Inside the Facility: Where It All Happens

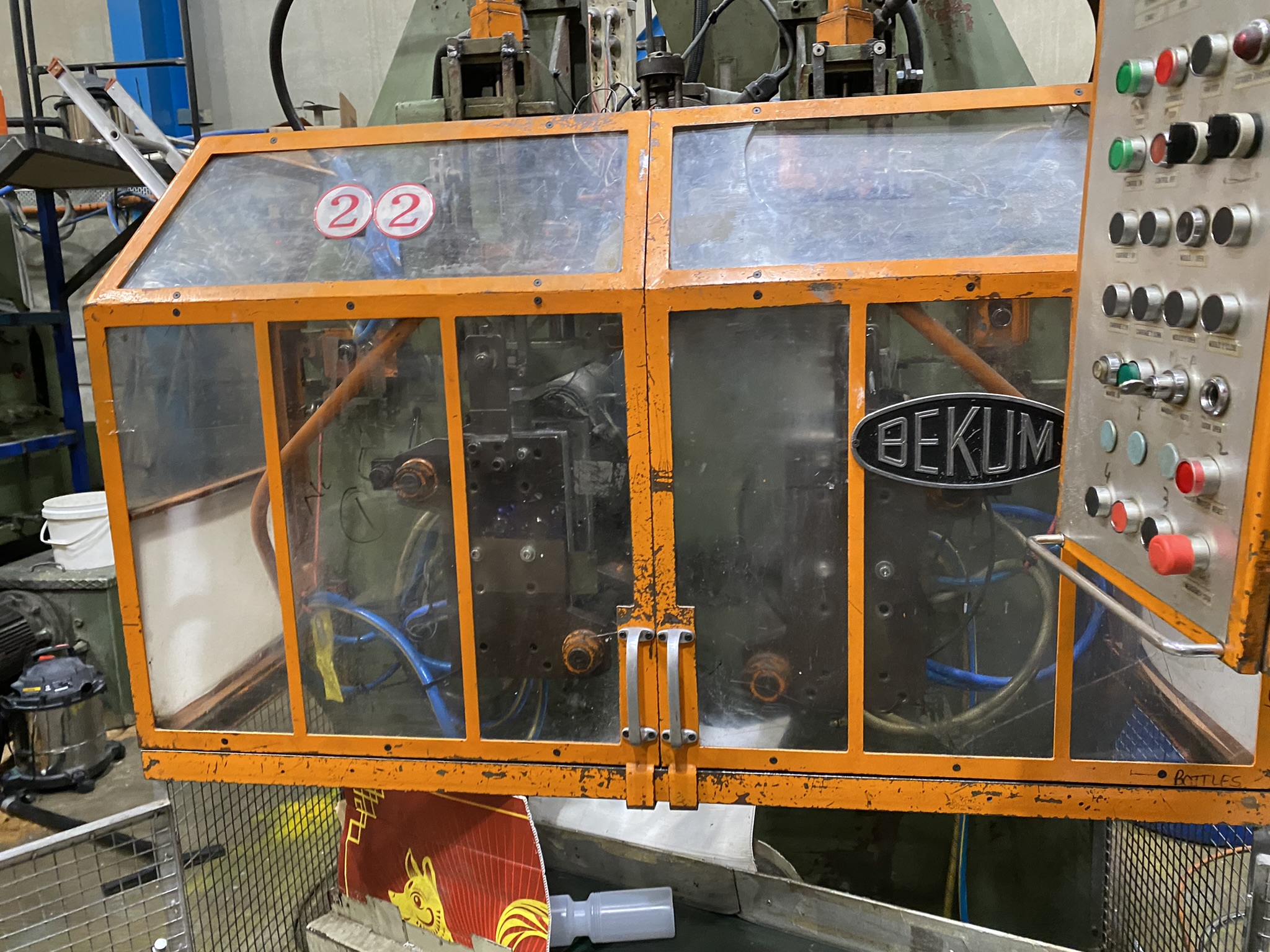

We recently visited the production site where our Australian-made bottles come to life. The facility is located right here on home soil and is equipped with:

- Food-grade certified machinery (monthy council inspections ensure this)

- Injection moulding stations that shape every bottle from scratch

- Automated assembly lines for lids, seals, and caps

- Eco-focused operations, including recycled plastic processing. All faulty bottles and offcuts, we throw into a big bin, which then gets re-processed.

Each bottle starts as a blank form and ends up a fully finished, branded item — all under one roof. We captured behind-the-scenes photos of the process, showing bottles being pressed, printed, and packed for dispatch. (Scroll down for images.).

The process starts like this to produce squeezy plastic bottles

- Resin Pellets (also known as Nurdles) are selected based on colour (there is a huge array of colours to choose from)

- Pellets are then melted into liquid

- The molten plastic is formed into a hollow tube (parison), placed in a mould, and expanded with compressed air to match the bottle’s shape.

- The mould cools the plastic until solid, then opens to release the formed bottle.

- When cooled, plastic bits will be trimmed off.

- Bottles ready for branding

Custom Branding, Done Right and Done Locally

Once the bottles are made, they’re sent directly to our in-house printing studio. Here, we print using a wide array of custom branding techniques and technology. This includes digital direct print and rotary screen print.

🤔 FAQs: What Buyers Want to Know

Is it more expensive to go Australian-made?

Not always. The price is very comparable. This is because shipping bottles means shipping a lot of empty air, which becomes very expensive to ship. The final price is more or less the same.

Can I see the production process?

Yes, call us and ask for Charles. He can organise an exclusive factory tour for your organisation. You get to take images, and he will walk you through every step—from tooling to final delivery.

Do I need a large budget for local production?

Not at all. Our Australian-made bottle options start at low MOQs (minimum order quantities) of 100 pieces, and bulk pricing is available as volumes increase.

Are these bottles eco-friendly?

Yes. They’re reusable, BPA-free, recyclable, and created in facilities prioritising low-waste operations.

Final Thoughts: Why “Australian Made“ Adds Value

Our customers now ask us lots of questions before they make wholesale purchases of bottles. It is clear from their questions that they care where things come from. Fast lead times have always been a common question, but now topics like packaging waste and ethical sourcing are asked daily. When you choose Australian-made custom bottles, you’re not just making a smart purchasing decision—you’re making a statement—one that says your brand backs quality, speed, and sustainability.

📞 Call 1300 858 288 or reach out to our team to explore our full range of custom water bottles made in Australia. You’ve seen where they’re made. Now let’s make them yours.

About the Author