Australian-made promotional items are often associated with supporting local jobs, sustainability, and national pride. While these factors are important, they do not always drive purchasing decisions.

In practice, Australian-made products excel in situations where speed, control, reliability, or stakeholder expectations are more important than unit price. In this article, we’ve discussed these scenarios to help you decide if choosing this type of merch is practical.

When “Australian-made” becomes a solution?

This type of merch is rarely the lowest-cost option. They are most valuable when factors such as timing, risk reduction, flexibility, or accountability take priority over price.

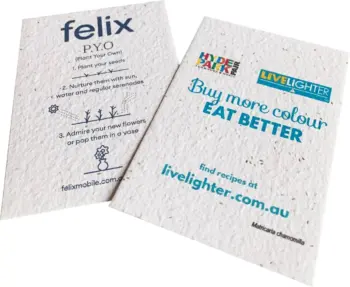

Example of products that are Made in Australia

Below are five situations where choosing Australian-made is often the most practical decision.

1.When lead times are tight, and dates can’t move

Events have fixed dates. Conferences, launches, community days, and internal milestones cannot be rescheduled, and compressed timelines make offshore supply chains a liability. For buyers working toward a fixed deadline, local production often determines whether delivery is successful or whether a backup option is required.

Australian-made products remove several layers of uncertainty:

- No international shipping delays

- No port congestion risk

- Faster production turnaround

- Easier communication when timelines shift

See our range of Australian-Made products here

2.When accuracy and consistency matter more than volume

For campaigns where:

- Colour matching is critical

- Brand guidelines are strict

- Product consistency across units is essential

Australian manufacturing provides greater control. The ability to review samples promptly, adjust artwork without significant delays, and resolve issues locally reduces the risk of receiving products that are technically acceptable but not usable in practice.

This is especially relevant for:

- Government departments

- Education institutions

- Corporate rebrands

- National campaigns with reputational exposure

3.When stakeholders expect local sourcing

In some sectors, Australian-made is not simply preferred; it is expected. The product’s origin is integral to the message. Using Australian-made items aligns procurement decisions with organisational values and public accountability, without requiring extensive explanation.

This commonly applies to:

- Councils and government programs

- Community and not-for-profit organisations

- Indigenous partnerships

- Public-facing initiatives with local audiences

4.When flexibility is required mid-project

Projects often change. Quantities may increase, messaging can evolve, and delivery addresses may multiply. Offshore orders often require early, fixed decisions. Local production allows buyers to adapt without exceeding budgets or timelines, which is a significant advantage in real-world campaigns.

Australian-made promotional products allow for:

- Smaller top-up runs

- Artwork tweaks without restarting production

- Faster reprints if demand exceeds expectations

5.When risk reduction outweighs cost savings

The hidden cost of promotional products is not always financial; it can also be reputational. Missed deadlines, quality issues, or last-minute substitutions don’t just affect a campaign — they reflect on the people who approved the decision.

Australian-made products reduce risk by:

- Shortening the supply chain

- Improving visibility and accountability

- Enabling faster and more transparent problem-solving

Australian-made vs offshore

Neither option is universally better. The value of Australian-made products depends on when they are used, not just on their perceived benefits.

What experienced buyers do differently?

Experienced Australian buyers do not default to local or offshore options; they segment their approach. They use Australian-made products for:

- Time-critical campaigns

- Stakeholder-sensitive projects

- Pilot runs and test programs

And offshore supply for:

- Long-term, repeatable stock

- High-volume giveaways with flexible timing

What We Think?

Australian-made promotional products are not a universal solution. They are a strategic choice. At Cubic Promote, we help clients determine where local manufacturing genuinely reduces risk or improves outcomes, and where offshore production is more appropriate. The strongest campaigns are not built on assumptions; they are built on selecting the right supply model for each project. When Australian-made is the practical choice, it shows.

Sale

Sale

Corporate Uniforms

Corporate Uniforms Eco Apparel

Eco Apparel Hoodies & Sweaters

Hoodies & Sweaters Jackets

Jackets Kids' Clothes

Kids' Clothes Other Apparel

Other Apparel Polo Shirts

Polo Shirts Socks

Socks Shoes

Shoes Sports Bottoms

Sports Bottoms Sports Uniforms

Sports Uniforms Tee Shirts

Tee Shirts Workwear

Workwear

Briefcases

Briefcases Dry Bags

Dry Bags Laptop

Laptop Satchels

Satchels Specialised Bags

Specialised Bags Tote Bags

Tote Bags

Beanies

Beanies Caps

Caps Straw Hats

Straw Hats

Bottled Water

Bottled Water Drinkware Gift Sets

Drinkware Gift Sets Glass & Poly Cups

Glass & Poly Cups Mason Jars

Mason Jars Stubby | Bar & Drinkware

Stubby | Bar & Drinkware Wines

Wines

Business Card Holders

Business Card Holders IT Gift Sets

IT Gift Sets Tech Computers

Tech Computers

Beach Towels

Beach Towels Car Accessories

Car Accessories Golf

Golf Lighters

Lighters Picnic Gear

Picnic Gear Sports Items

Sports Items Sunscreens

Sunscreens

Markers

Markers Post-It & Sticky Notes

Post-It & Sticky Notes

Card Decks

Card Decks Coin Banks

Coin Banks Conference Toys

Conference Toys Event Toys

Event Toys Frisbees

Frisbees Games & Puzzles

Games & Puzzles Kids

Kids Plush Toys

Plush Toys

Print | Signage

Print | Signage

Antibacterial

Antibacterial Eco Products

Eco Products Gift Box Sets

Gift Box Sets Homeware

Homeware Pet Products

Pet Products Personal Care

Personal Care Occasion Ideas

Occasion Ideas