If you’ve ever approved artwork and still thought, “That blue looks different in real life”, you’re not alone. Colour accuracy is one of the most important and most misunderstood parts of branded merchandise. At Cubic Promote, we don’t rely on screens, guesses, or settling for ‘close enough.’

We follow a step-by-step process to make sure your brand colours look right on the product, under different lighting, and when your audience sees them. Here’s exactly how we do it and why it matters for Australian B2B buyers who order in bulk.

Why Colour Accuracy Is Non-Negotiable for B2B Brands?

Your logo colour isn’t decoration. It’s recognition, trust, and consistency. When colour is off, even slightly:

- Brands look less established.

- Marketing teams get internal pushback.

- Procurement loses confidence

- Events feel less polished.

And once thousands of units are printed? There’s no undo button. That’s why colour checking at Cubic Promote happens before, during, and after production.

Step 1: We Start with the Right Colour Reference (Always)

Everything begins with clarity. Pantone references are especially important because screens can be misleading. Monitors, brightness, and colour profiles all vary. PMS gives us a physical, standard colour reference instead of relying on guesswork.

We ask for:

- PMS (Pantone) colour codes were available

- Vector artwork (AI, EPS, or high-res PDF)

- Clear brand guidelines, if you have them

Step 2: We Match Colour to the Decoration Method

This is a step that many suppliers overlook: Colour behaves differently depending on how it’s applied. We treat each branding method differently.

Pad Printing

With methods like pad printing on promotional items, colour is mixed as ink and transferred via a silicone pad. Pad printing is precise, but small changes in pressure or surface can shift the colour slightly. We plan for that from the start.

We check:

- Ink formulation vs PMS reference

- Ink density on curved or textured surfaces

- How the substrate (plastic, metal, rubber) affects tone

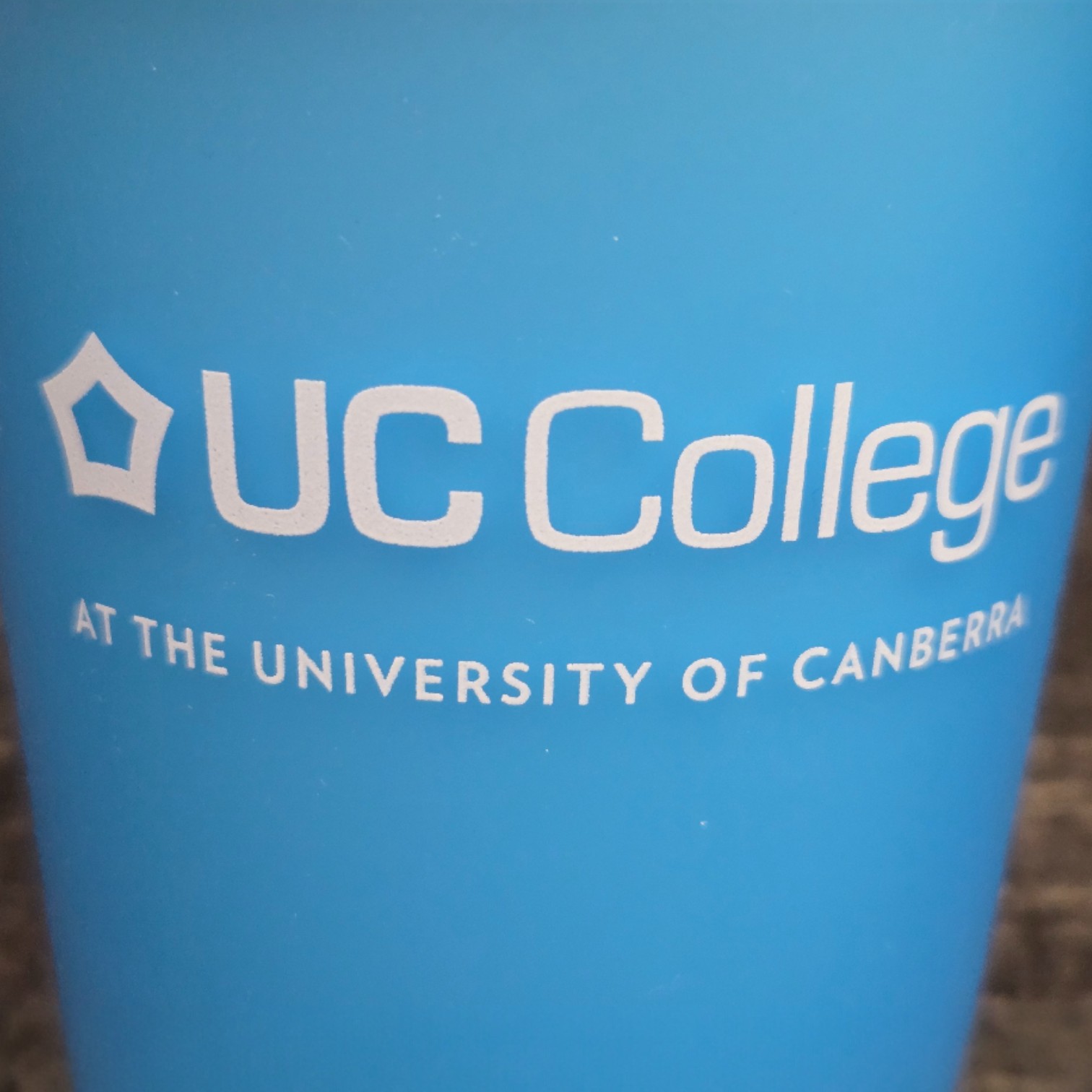

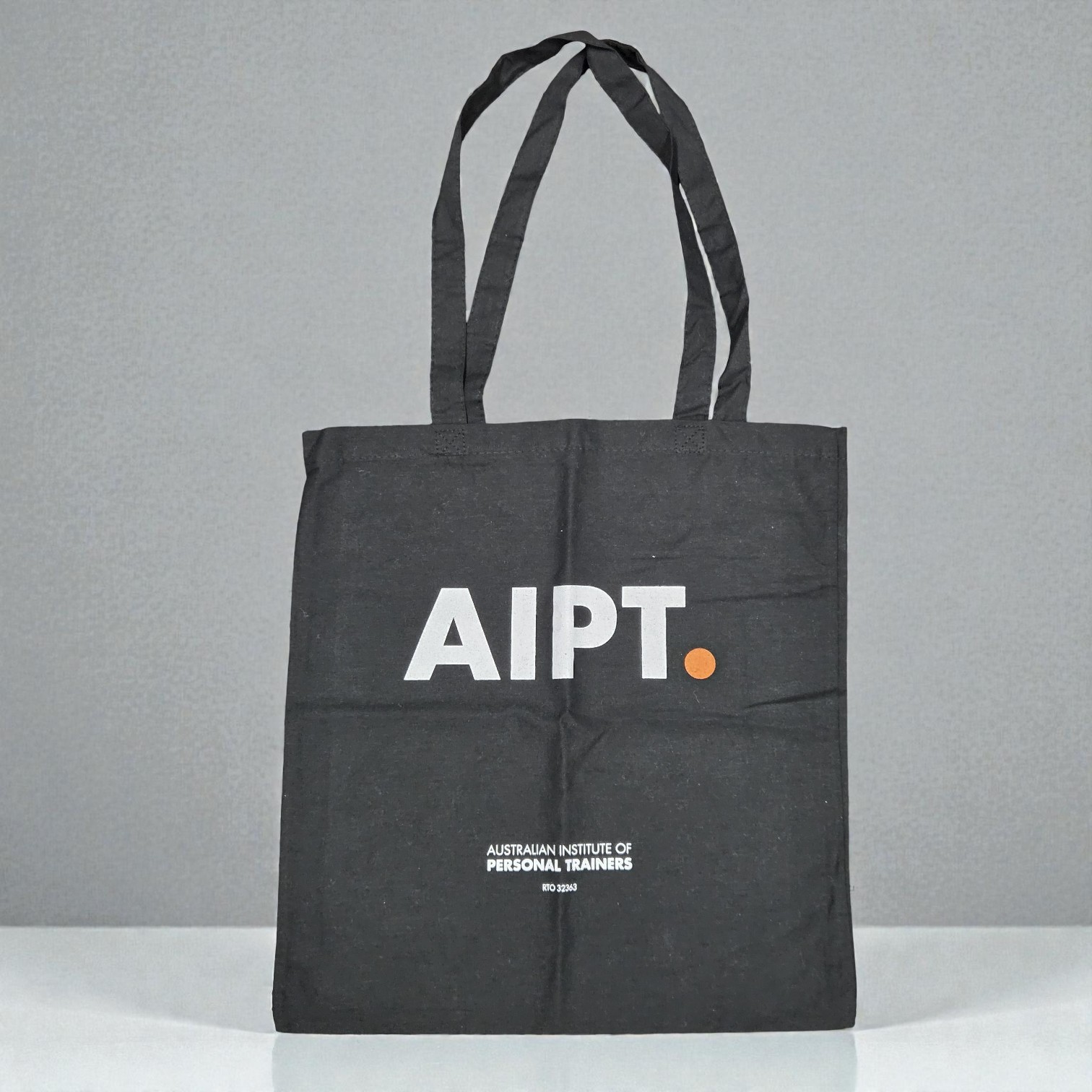

Screen Printing

For larger print areas, especially on apparel and bags, screen printing is the go-to for promotional items. A navy colour printed on cotton will not look the same as it does on polyester. We test for that before approving production runs.

Here we assess:

- Ink opacity (especially on dark fabrics)

- Underbase requirements

- Fabric absorption

Digitally Printed Labels

With digitally printed labels, colour accuracy depends heavily on calibration. Digital printing is flexible, but only if the machines are properly calibrated. Ours are.

We check:

- Printer profiles

- CMYK to PMS conversions

- Gloss vs matte finishes (they change how colour is perceived)

Embroidery

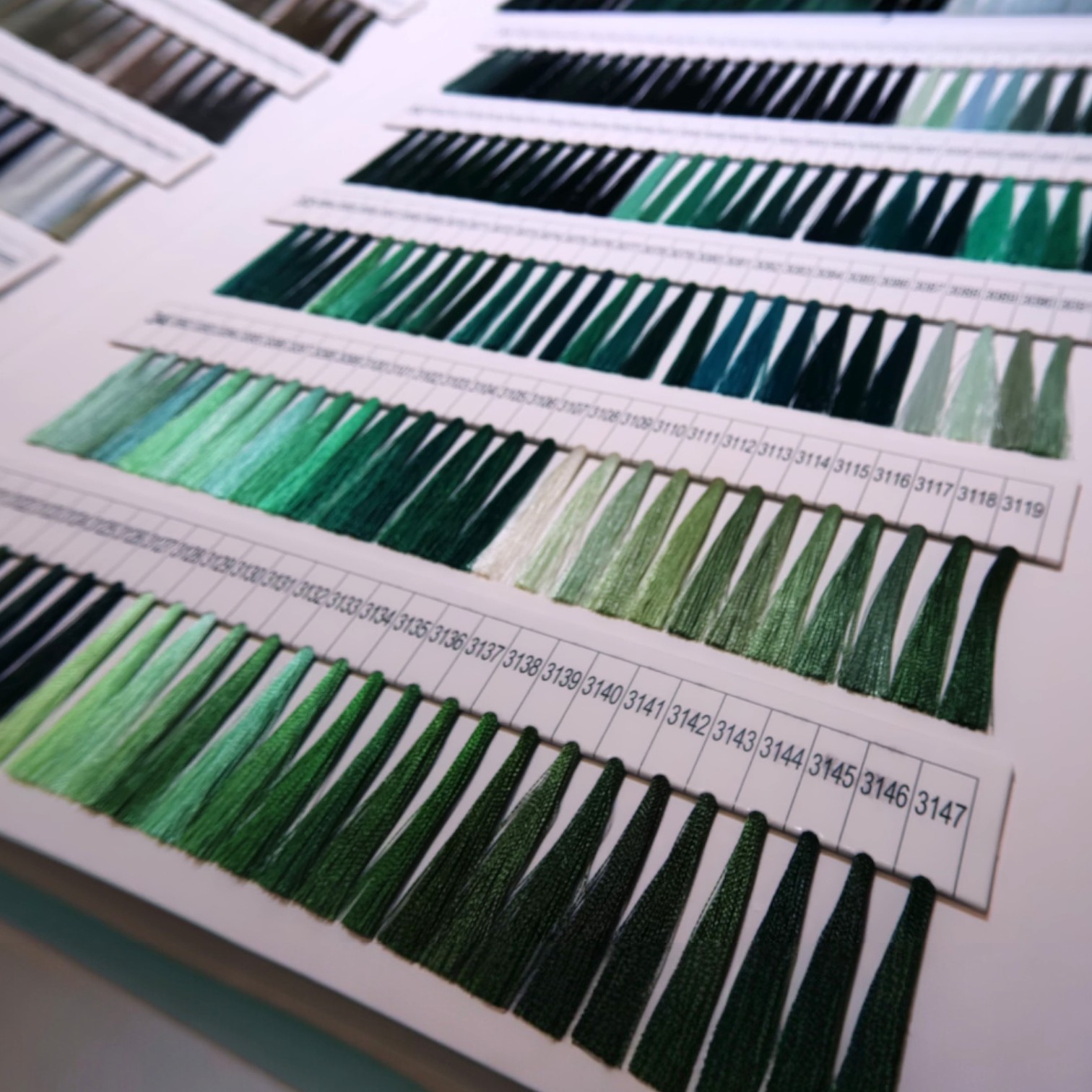

Embroidery on promotional items is a completely different process. Thread isn’t ink. Some colours do not translate perfectly into thread. When this happens, we let you know early and suggest the closest and best-looking alternative.

We evaluate:

- Thread colour libraries vs PMS

- Stitch density (dense stitching deepens colour)

- Direction of stitch, since it affects how the colour reflects light

Step 3: Physical Sampling, Not Just Digital Proofs

Digital proofs are useful. They are not the final word. This is where theory meets reality. Ink on a screen is not the same as ink on a product. We only sign off when we’re happy with what’s physically in front of us.

For colour-critical jobs, we review:

- Pre-production samples

- Strike-offs

- Production samples from the actual batch

Step 4: The Indoor Light Check (Office Reality Test)

Most branded merchandise lives indoors. Some colours skew cooler or warmer under artificial light. If we see it, we catch it here.

We check colour under:

- Office lighting

- Fluorescent lights

- Warm indoor LEDs

This shows how your logo will look:

- On desks

- In meeting rooms

- At conferences

- In onboarding kits

Step 5: The Natural Sunlight Check (Real-World Test)

This is a step many suppliers skip, but we do not. We take the finished product outside. If a colour only looks good inside a warehouse, that is not good enough.

Natural sunlight reveals:

- Undertones you won’t see indoors.

- Saturation shifts

- Contrast issues on certain materials

Why this matters:

- Events happen outdoors

- Staff use merch on the go.

- Logos are photographed in daylight.

- Social content lives under natural light.

Step 6: Side-by-Side Brand Consistency Review

We often line up:

- New production samples

- Previous orders

- Existing brand assets

This ensures:

- Repeat orders stay consistent.

- Multi-item kits look cohesive.

- Different products don’t clash visually.

This step is especially important for:

- Large corporates

- Government departments

- Ongoing uniform or merch programs

Consistency builds trust, and we make sure to protect it.

Common Colour Challenges (And How We Handle Them)

No surprises. No last-minute panic.

Why This Process Matters for Bulk Orders?

When you’re ordering hundreds or thousands of units:

- Small colour errors multiply fast.

- Reprints cost time and money.

- Stakeholders notice

Our colour accuracy checks protect:

- Your brand reputation

- Your internal approvals

- Your project timelines

And, honestly, your peace of mind.

The Cubic Promote Difference

We don’t just print logos. We safeguard brands. Colour accuracy isn’t one step. It’s a system. From receiving your artwork to the final sunlight checks, we treat your branding as if it were our own, because once it is out there, it represents you.

If you’re planning a colour-critical project and want confidence before you commit, talk to our team early. We will guide you through the best decoration method, material choice, and colour approach before anything goes to print. That’s how we keep Australian brands looking sharp.

Sale

Sale

Corporate Uniforms

Corporate Uniforms Eco Apparel

Eco Apparel Hoodies & Sweaters

Hoodies & Sweaters Jackets

Jackets Kids' Clothes

Kids' Clothes Other Apparel

Other Apparel Polo Shirts

Polo Shirts Socks

Socks Shoes

Shoes Sports Bottoms

Sports Bottoms Sports Uniforms

Sports Uniforms Singlets

Singlets Tee Shirts

Tee Shirts Workwear

Workwear

Briefcases

Briefcases Dry Bags

Dry Bags Laptop

Laptop Satchels

Satchels Specialised Bags

Specialised Bags Tote Bags

Tote Bags

Beanies

Beanies Caps

Caps Straw Hats

Straw Hats

Bottled Water

Bottled Water Drinkware Gift Sets

Drinkware Gift Sets Glass & Poly Cups

Glass & Poly Cups Mason Jars

Mason Jars Stubby | Bar & Drinkware

Stubby | Bar & Drinkware Wines

Wines

Business Card Holders

Business Card Holders IT Gift Sets

IT Gift Sets Tech Computers

Tech Computers

Beach Towels

Beach Towels Car Accessories

Car Accessories Golf

Golf Lighters

Lighters Picnic Gear

Picnic Gear Sports Items

Sports Items Sunscreens

Sunscreens

Markers

Markers Post-It & Sticky Notes

Post-It & Sticky Notes

Card Decks

Card Decks Coin Banks

Coin Banks Conference Toys

Conference Toys Event Toys

Event Toys Frisbees

Frisbees Games & Puzzles

Games & Puzzles Kids

Kids Plush Toys

Plush Toys

Print | Signage

Print | Signage

Antibacterial

Antibacterial Eco Products

Eco Products Gift Box Sets

Gift Box Sets Homeware

Homeware Pet Products

Pet Products Personal Care

Personal Care Occasion Ideas

Occasion Ideas