What is “Epoxy Dome Branding”

What is Full-Colour Epoxy Dome Printing?

Full-colour epoxy dome printing involves a clear, resin-based dome over a printed design. This technique creates a raised, bubble-like effect that protects the print under it and adds a smooth, glossy finish. Unlike traditional flat printing, this branding method adds depth and texture to your logos.

This branding method stands out because of its high-definition, full-colour printing capabilities. The resin coating enhances the vibrance of your colours, ensuring your logos look striking from every angle. This branding method also provides a durable finish.

How the Epoxy Dome Method is Applied

Get that glossy, raised finish for your logos and designs! The epoxy dome printing method involves the following:

- Design Printing: We will print your logo or design full-colour on a high-quality vinyl or polyester substrate.

- Resin Application: The manufacturer carefully pours a clear, liquid epoxy resin over the printed surface. This forms a smooth and protective dome for that 3D effect.

- Curing Process: We will leave the resin to airdry or undergo UV curing to harden.

- Final Touches: Once fully cured (dried), we will cut the finished product to size and apply it to the desired surface, such as metal, acrylic, or plastic.

This meticulous process ensures a glossy look that lasts over time, making it ideal for premium corporate branding.

Advantages

The advantage of this branding method is that it offers exceptional durability. The epoxy coating protects against scratches, fading, and environmental damage. The epoxy will also keep your prints sharp and clear for the long haul

Epoxy branding works on various surfaces, such as metal, plastic, acrylic, and vinyl. This print method allows us to adjust the dome to different sizes and shapes. Also, it allows us to personalise the dome on various products, including small badges, keychains, and product labels.

Disadvantages

While epoxy dome printing is a premium branding method, there are some factors we want you to keep in mind before choosing this method:

- Higher Cost: Due to the added resin coating and curing process, this method tends to be more expensive than traditional flat printing.

- Time-Intensive Production: Our curing process takes time, which can extend production turnaround times.

- Material Restrictions: This method works best on smooth surfaces only. Textured and porous materials are not suitable.

Surfaces Suitable for Epoxy Dome Printing

Choosing the right surface is crucial for achieving the best results with epoxy dome printing. This method works best on smooth, non-porous surfaces. This method works best on:

- Vinyl: Best on sticker-style applications and promotional labels.

- Metal: Great for keyrings, nameplates, and corporate gifts.

- Acrylic: Provides a sleek, high-end look for branded items.

- Polyester: Frequently used for durable, long-lasting labels and tags.

Examples of Promotional Items Using Epoxy Printing

This printing method is ideal for a range of high-quality promotional products, including:

- Branded Keyrings

- Custom Name Badges

- Promotional Bottle Openers

- USB Flash Drives

- Fridge Magnets

- Lapel Pins

- Luggage Tags

These examples showcase the versatility and high-quality appearance of epoxy dome printing across different industries and applications.

Sale

Sale

Corporate Uniforms

Corporate Uniforms Eco Apparel

Eco Apparel Hoodies & Sweaters

Hoodies & Sweaters Jackets

Jackets Kids' Clothes

Kids' Clothes Other Apparel

Other Apparel Polo Shirts

Polo Shirts Socks

Socks Shoes

Shoes Sports Bottoms

Sports Bottoms Sports Uniforms

Sports Uniforms Tee Shirts

Tee Shirts Workwear

Workwear

Briefcases

Briefcases Dry Bags

Dry Bags Laptop

Laptop Satchels

Satchels Specialised Bags

Specialised Bags Tote Bags

Tote Bags

Beanies

Beanies Caps

Caps Straw Hats

Straw Hats

Bottled Water

Bottled Water Drinkware Gift Sets

Drinkware Gift Sets Glass & Poly Cups

Glass & Poly Cups Mason Jars

Mason Jars Stubby | Bar & Drinkware

Stubby | Bar & Drinkware Wines

Wines

Business Card Holders

Business Card Holders IT Gift Sets

IT Gift Sets Tech Computers

Tech Computers

Beach Towels

Beach Towels Car Accessories

Car Accessories Golf

Golf Lighters

Lighters Picnic Gear

Picnic Gear Sports Items

Sports Items

Markers

Markers Post-It & Sticky Notes

Post-It & Sticky Notes

Card Decks

Card Decks Coin Banks

Coin Banks Conference Toys

Conference Toys Event Toys

Event Toys Frisbees

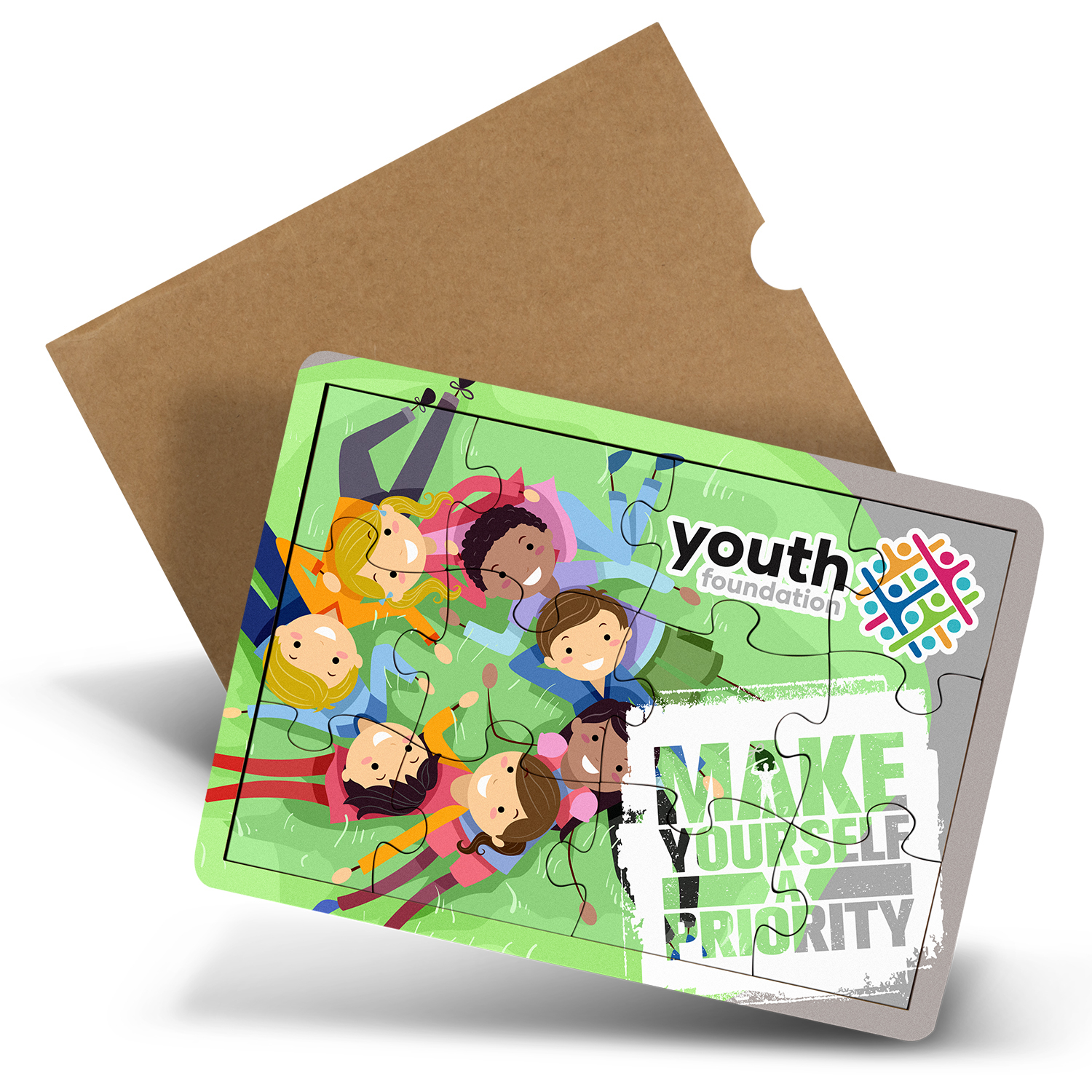

Frisbees Games & Puzzles

Games & Puzzles Kids

Kids Plush Toys

Plush Toys

Print | Signage

Print | Signage

Antibacterial

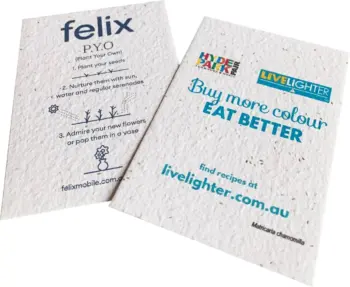

Antibacterial Eco Products

Eco Products Gift Box Sets

Gift Box Sets Homeware

Homeware Pet Products

Pet Products Personal Care

Personal Care Occasion Ideas

Occasion Ideas