Rotary Screen Print on Promotional Items

Last Updated: 26 July 2025

Rotary printing utilises plates on a rotating cylinder. The technique is to roll a product across cylinders which will turn produce printing all the way around products without breaks. This is one of the best printing methods for high volume print in terms of speed.

Screen printing equipment works equally well on to various surfaces such as paper, cardboard and plastic. For branding promotional items that is too big for pad printing, rotary screen print is a great alternative. Rotary screen printing is a popular technique used in the printing industry to create high-quality and vibrant prints on a wide range of materials.

This type of printing involves using a cylindrical mesh fabric that is stretched onto a frame, which is then rotated over the surface of the object being printed. Ink is poured over the mesh fabric, which adheres to the raised areas, resulting in an image or design that is applied to the object.

It has been around for nearly half a century. This branding method produces vibrant prints on both hard and soft surfaces, including textiles, rigid plastics, paper, and metal substrates. Not only does it provide superior print quality with every job. Rotary printing also offers incredible speeds compared to other types of printing methods.

Tips On Designing A Logo Or Image For Rotary Screen Printing

When designing a logo or image for rotary screen printing there are several key points you should take into consideration before beginning production:

The first is color selection; rotary screen printing works best with a minimum number of solid colors so try not create too many gradients or different shades which will result in an inconsistent output across different surfaces including textiles as they tend to absorb pigment differently than other substrate mediums.

Secondly, pay attention to line weights; make sure lines are thick enough so that after shrinking, aging or fading they don’t lose their definition completely or look too ‘thin’ compared against surrounding elements because such mistakes could detrimentally affect the overall look depending on your design intent and application choice (t-shirt vs water bottle).

Lastly, always remember that complex designs come at a cost. So, keep shapes simple because intricate patterns often require double color applications during production. This increases both production time and cost per unit, which can become expensive if not managed properly. However, when done correctly, it can still produce excellent results.

Advantages

- Extreme high degree of control and accuracy

- Cost savings

- Environmental friendly

- Steady and reliable performance

- Correct and smooth label sticking

Promotional Items that are commonly branded using Rotary Screen Prints

-

- Promotional drink bottles

- Printed paper cones

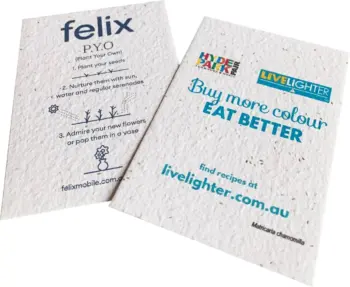

- Branded novelties

- Customised flasks

- Personalised travel mugs

How Rotary Screen Printing Works

Watch as we reveal the process on how rotary screen printing works! Perfect for mass production, this process ensures fast, consistent, and detailed prints. Let’s dive in!

Sale

Sale

Corporate Uniforms

Corporate Uniforms Eco Apparel

Eco Apparel Hoodies & Sweaters

Hoodies & Sweaters Jackets

Jackets Kids' Clothes

Kids' Clothes Other Apparel

Other Apparel Polo Shirts

Polo Shirts Socks

Socks Shoes

Shoes Sports Bottoms

Sports Bottoms Sports Uniforms

Sports Uniforms Singlets

Singlets Tee Shirts

Tee Shirts Workwear

Workwear

Briefcases

Briefcases Dry Bags

Dry Bags Laptop

Laptop Satchels

Satchels Specialised Bags

Specialised Bags Tote Bags

Tote Bags

Beanies

Beanies Caps

Caps Straw Hats

Straw Hats

Bottled Water

Bottled Water Drinkware Gift Sets

Drinkware Gift Sets Glass & Poly Cups

Glass & Poly Cups Mason Jars

Mason Jars Stubby | Bar & Drinkware

Stubby | Bar & Drinkware Wines

Wines

Business Card Holders

Business Card Holders IT Gift Sets

IT Gift Sets Tech Computers

Tech Computers

Beach Towels

Beach Towels Car Accessories

Car Accessories Golf

Golf Lighters

Lighters Picnic Gear

Picnic Gear Sports Items

Sports Items Sunscreens

Sunscreens

Markers

Markers Post-It & Sticky Notes

Post-It & Sticky Notes

Card Decks

Card Decks Coin Banks

Coin Banks Conference Toys

Conference Toys Event Toys

Event Toys Frisbees

Frisbees Games & Puzzles

Games & Puzzles Kids

Kids Plush Toys

Plush Toys

Print | Signage

Print | Signage

Antibacterial

Antibacterial Eco Products

Eco Products Gift Box Sets

Gift Box Sets Homeware

Homeware Pet Products

Pet Products Personal Care

Personal Care Occasion Ideas

Occasion Ideas