Pad Printing on Promotional Products

Last Updated: 26 July 2025

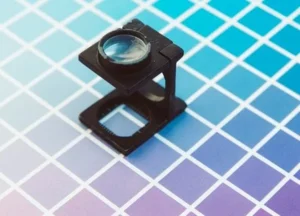

Pad printing is a leading method for promotional decoration due to its simple technique that effectively brands products in vibrant colors on flat surfaces. Despite the rise of digital printing, pad printing remains popular for its consistency and affordability, making it a practical choice for many businesses.

What is Promotional Pad Printing?

Promotional pad printing is the most sought-after and cost-effective way to decorate flat, smooth products, providing a crisp finish ideal for bulk items like branded notebooks, stress balls, and reusable coffee cups. The process involves transferring ink from a metal or plastic plate featuring your custom design, allowing for accurate branding in large quantities. For more information on our pad printing techniques, keep reading!

How Do We Brand Using Pad Printing?

To begin the pad printing process, first, we secure a high-quality logo or slogan file, to ensure it’s in AI, EPS, or vectorized PDF format. Then, once you approve the artwork, immediately we create a positive film that resembles traditional camera film but with the image reversed. Next, we craft a cliche, which serves as the printing plate. Naturally, depending on your design, we may use silicone, plastic, or steel for these plates.

After transferring the approved artwork onto the plate, next we expose it to UV light to etch the design, following repeating this for each colour in your logo, since each requires a unique plate. Then after setting the design, at last we print your design directly onto the promotional products. Subsequently we apply thick and durable ink according to your specific colour requirements.

Additionally, if your merchandise has glossy finish or film coating, of course we perform special pre-treatment to ensure ink adherence. This extra step accordingly enhances the print’s durability.

What Are The Advantages of Pad Printing?

– Versatile! Pad printing works especially on any flat and smooth surface.

– Economical! You can achieve great results with pad printing because the print setup is both affordable and straightforward.

– Fast! Since ink dries quickly during the pad printing, consequently we can pack your promotional products and ship them out ASAP.

– Detailed! Unlike silk screen printing, pad printing achieves fine detail, thus making it ideal for complex logos.

– Colours! Although it may be slightly more costly, pad printing allows for multiple print colours, unlike screen printing. Furthermore, some machines now offer 4-color processing;, so feel free to ask our sales team for more information!

What Are The Disadvantages of Pad Printing?

pad printing a pen

– Admittedly, we cannot achieve full photographic colour printing with pad printing.

– Furthermore, we cannot print colour gradients; however, we can use spot Pantone colours.

– Additionally, it’s important to note that printing may chip or fade over time due to everyday wear. Unfortunately, there is no way to prevent this.

– Moreover, the branding area for pad printing is limited because the size of the pad absorbs the ink. As a result, we cannot print large designs effectively.

– Consequently, we do not recommend pad printing for fabric materials.

– Lastly, we try to closely match your desired Pantone colour, but we cannot guarantee an exact match to what you see on your computer monitor.

Example of a Pad Printed Cup

Here is an Australian Made Reusable Coffee Cup branded using a pad print process.

Items We Customise Using Pad Printing

- Pens

- Personalised Keychains

- USB Drives

- Lanyards

- Stress Balls

- Mugs

- Custom Staplers

- Water Bottles

- Notebooks

- Coasters

- Fridge Magnets

- Desktop Clocks

- Phone Cases

- Custom Sunglasses

- Wristbands (silicone)

- Custom Flashlights

- Highlighters

Sale

Sale

Corporate Uniforms

Corporate Uniforms Eco Apparel

Eco Apparel Hoodies & Sweaters

Hoodies & Sweaters Jackets

Jackets Kids' Clothes

Kids' Clothes Other Apparel

Other Apparel Polo Shirts

Polo Shirts Socks

Socks Shoes

Shoes Sports Bottoms

Sports Bottoms Sports Uniforms

Sports Uniforms Tee Shirts

Tee Shirts Workwear

Workwear

Briefcases

Briefcases Dry Bags

Dry Bags Laptop

Laptop Satchels

Satchels Specialised Bags

Specialised Bags Tote Bags

Tote Bags

Beanies

Beanies Caps

Caps Straw Hats

Straw Hats

Bottled Water

Bottled Water Drinkware Gift Sets

Drinkware Gift Sets Glass & Poly Cups

Glass & Poly Cups Mason Jars

Mason Jars Stubby | Bar & Drinkware

Stubby | Bar & Drinkware Wines

Wines

Business Card Holders

Business Card Holders IT Gift Sets

IT Gift Sets Tech Computers

Tech Computers

Beach Towels

Beach Towels Car Accessories

Car Accessories Golf

Golf Lighters

Lighters Picnic Gear

Picnic Gear Sports Items

Sports Items

Markers

Markers Post-It & Sticky Notes

Post-It & Sticky Notes

Card Decks

Card Decks Coin Banks

Coin Banks Conference Toys

Conference Toys Event Toys

Event Toys Frisbees

Frisbees Games & Puzzles

Games & Puzzles Kids

Kids Plush Toys

Plush Toys

Print | Signage

Print | Signage

Antibacterial

Antibacterial Eco Products

Eco Products Gift Box Sets

Gift Box Sets Homeware

Homeware Pet Products

Pet Products Personal Care

Personal Care Occasion Ideas

Occasion Ideas