Let me take you around the back into a bottle-making factory. We make a few styles of promotional plastic bottles here in Australia (yes, manufacturing is not dead in Australia). The process of bottles is fun and an eye-opener for many. I’ll stop talking now; let’s dive in and see how exactly a bag of plastic pellets becomes a bottle.

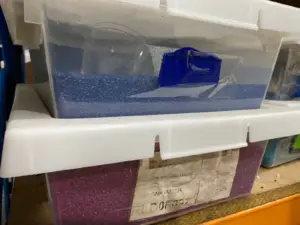

Bag of Plastic Pellets

A bag of plastic pellets into drink bottles is a great way to reduce plastic waste and help the environment. It‘s an innovative way to reuse plastic and turn it into something useful and sustainable. The process of turning plastic pellets into drink bottles is quite simple: the pellets are melted down and then extruded into a bottle shape.

The bottles are then cooled, filled, and sealed. This method of repurposing plastic can help reduce the amount of plastic waste in landfills, while also providing an affordable and sustainable way of producing drink bottles. Furthermore, the process of melting and extruding the pellets into bottles can be done relatively quickly and cheaply, making it a viable solution for businesses and consumers alike.

It all starts with White Pellets to create a white bottle. Then, if we want to make a blue bottle (or any other colour), we sprinkle a few blue specs into the machine. You would be surprised, but only a few blue pellets are enough to make a dark navy blue coloured bottle.

Making a Polypropylene Bottle

Today we will be making a bottle using the material polypropylene. This material produces a quality soft feel bottle with either solid or translucent colours. Popular amongst many sporting teams and school kids around Australia, you cannot go wrong with this bottle style. The polypropylene is used to make both the bottle and the lid.

Step 1: Plastic Pellets are sucked into a machine (a big one)

Step 2: The Pellets are melted inside a machine

Step 3: The pellets are squirted into a Mould

Step 4: Once set, the mould opens up and out pops a bottle

Step 5: Visual inspection.

When these bottles come out of the machine, they are warm and soft to the touch. Not all of them come out perfectly, though. For the ones with defects, we chuck them into a recycling machine to convert them back into pellets.

Repeat this process hundreds of times to create hundreds of bottles!

There are not a lot of bottle producers here in Australia nowadays. This facility is one of 3 Australia-wide that I know of. In my next post, I will talk about:

1) Bottle Branding

2) Bottle Recycling

3) Bottle Cleaning (inside the production stage)

Looking forward to showing you more behind-the-scenes information from promotional items manufacturing in Australia!

About the Author

Sale

Sale

Corporate Uniforms

Corporate Uniforms Eco Apparel

Eco Apparel Hoodies & Sweaters

Hoodies & Sweaters Jackets

Jackets Kids' Clothes

Kids' Clothes Other Apparel

Other Apparel Polo Shirts

Polo Shirts Socks

Socks Shoes

Shoes Sports Bottoms

Sports Bottoms Sports Uniforms

Sports Uniforms Tee Shirts

Tee Shirts Workwear

Workwear

Briefcases

Briefcases Dry Bags

Dry Bags Laptop

Laptop Satchels

Satchels Specialised Bags

Specialised Bags Tote Bags

Tote Bags

Beanies

Beanies Caps

Caps Straw Hats

Straw Hats

Bottled Water

Bottled Water Drinkware Gift Sets

Drinkware Gift Sets Glass & Poly Cups

Glass & Poly Cups Mason Jars

Mason Jars Stubby | Bar & Drinkware

Stubby | Bar & Drinkware Wines

Wines

Business Card Holders

Business Card Holders IT Gift Sets

IT Gift Sets Tech Computers

Tech Computers

Beach Towels

Beach Towels Car Accessories

Car Accessories Golf

Golf Lighters

Lighters Picnic Gear

Picnic Gear Sports Items

Sports Items

Markers

Markers Post-It & Sticky Notes

Post-It & Sticky Notes

Card Decks

Card Decks Coin Banks

Coin Banks Conference Toys

Conference Toys Event Toys

Event Toys Frisbees

Frisbees Games & Puzzles

Games & Puzzles Kids

Kids Plush Toys

Plush Toys

Print | Signage

Print | Signage

Antibacterial

Antibacterial Eco Products

Eco Products Gift Box Sets

Gift Box Sets Homeware

Homeware Pet Products

Pet Products Personal Care

Personal Care Occasion Ideas

Occasion Ideas